Ring benders and bracelet benders are specialized jewelry tools for shaping metal bands into circles and curves. They work by clamping a strip or wire and forcing it around a fixed mandrel or die. For example, one vendor touts a bracelet bender as “incredibly effective…to make consistent, perfectly shaped” cuff bracelets, hoops and even wrap rings. Likewise, heavy-duty ring benders use hardened dies to bend ring shanks – they can handle up to about 4 mm thickness of half-round, flat or oval stock. In operation, one end of the metal band is secured while the other end is pushed (often by a lever or thumbs) around the form, permanently deforming the metal into a circular shape. Because bending work-hardens metals like silver and gold, jewelers typically anneal the stock first to keep it soft and avoid cracks.

Principles of Operation

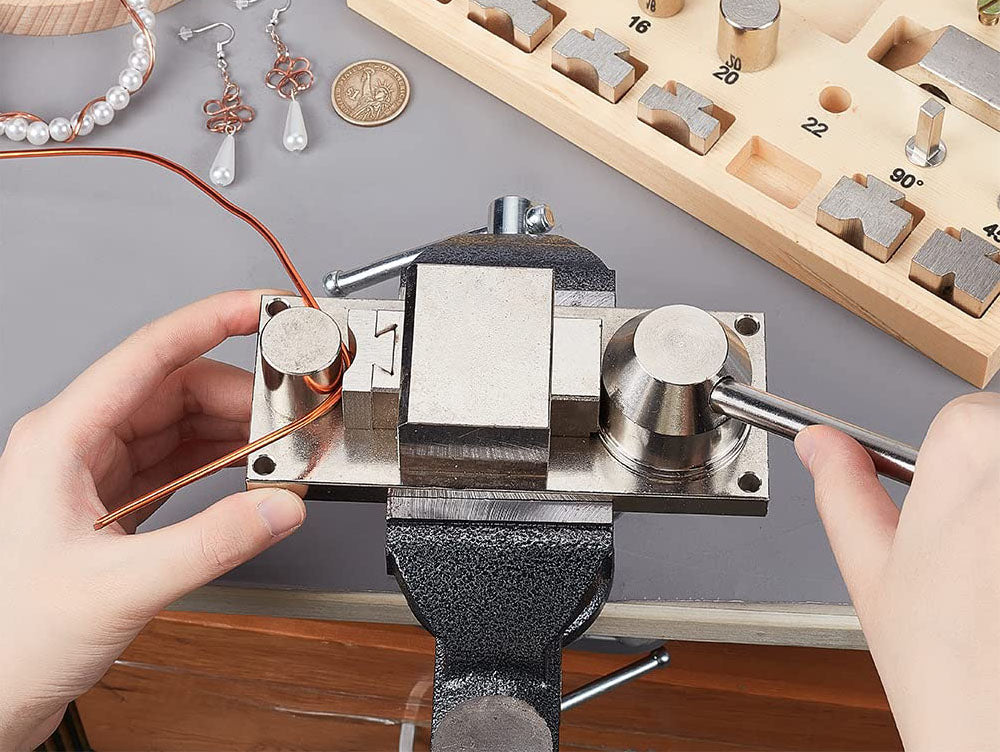

All these tools rely on plastic deformation. One end of the cut ring or cuff blank is clamped, and the free end is gradually forced past its yield point around a curved die or bar. As the metal bends, it takes the shape of the die. Many bench benders include sets of matching dies – for example, half-round or flat dies – so the jeweler can choose the right radius. A heavy-duty ring bender might have two “precision hardened and ground bending dies” that shape the metal without slippage. After bending, the curved band can be transferred to a mandrel or hammered into final shape. In practice, jewelers often bend the band twice: first to an approximate size, then on a slightly smaller form to snug the ends. One bench-bender user explains that after a first bend, he “selects the next smaller ring size…half moon…and give[s] it a little push” to make the joint fit tightly. Throughout, slow incremental bending and frequent checking on a mandrel ensure a uniform curve.

Manual Bending Tools

Ring Benders (hand tools). The simplest tools are plier-style benders. These have curved or flat jaws to bend wire or strip. Sturdy steel “German-style” bending pliers can shape heavy stock (up to about 10 ga, ~2.6 mm thick) into rings or coils. The jaws are often padded or fitted with nylon/Delrin inserts to grip without marring the metal. For example, flat-jaw bending pliers distribute force evenly across a strip so it “bends evenly without creating wrinkles or unsightly deformities”. Indeed, having uniform pressure is “essential when creating consistent curve or circular designs”. In use, the jeweler closes the plier a bit, slides the strip along the jaws, then closes more – repeating until a full circle is formed. If the gap is still open, the band can be re-bent over a smaller jaw or on a mandrel. Throughout, frequent annealing keeps the metal ductile.

Bench Ring Benders. More heavy-duty devices bolt to the bench and use a lever arm. Brands like Durston and Pepe Tools sell bench ring-benders with interchangeable dies. The jeweler clamps the ring blank (flat stock or half-round shank) between the dies and operates the lever to curve the metal. Because the dies are hardened and ground, they shape the band precisely (e.g. into round form up to 4 mm thick. Jewelers prize these for making perfect fits: after bending a ring into shape, one user notes he can then “snug the seam tight” by giving a small additional push on a smaller die. (This makes soldering easier, since the ring ends meet closely.) Bench ring benders often come with multiple dies and/or a nylon-die option so soft metals aren’t scratched.

Bracelet Benders (hand tools). The classic bracelet bender (invented by Joni Kisro and sold via Towed Studio) is essentially a clamping jig for cuffs and bangles. One end of a cuff blank is tightened into a screw clamp, and a free cylindrical bar acts as the form. As instructions note, the user “secure[s] one end of [the] bracelet…tighten[s] it down, then use[s] both thumbs to push the metal up and over the bar”. The operation is repeated on the other side (rotating the cuff). Because this tool has fixed curves, it reliably produces the correct cuff radius. (Indeed, the creator devised it “to quickly and reliably make just the right curves for cuff bracelets”; it was later adapted with smaller bars to form child-sized cuffs, hoop earrings, or even wrap rings) Jewelers also use smooth mandrels, PVC forms, or segmented bracelet jigs, but the Kisro/Urrea bender is praised as “arguably the easiest tool on the market to make consistent, perfectly shaped, comfortable bracelets”.

Aside from these, manual bending can use a small arbor press (with custom curved blocks) or even shot-peening machines for finish, but typical bench pliers and this screw-type bender cover most small-shop needs. In all manual methods, the key is to clamp one end, bend in stages, and check fit often on the intended mandrel.

Hydraulic and Powered Bending Machines

For large production or very stiff work, powered presses are used. A cam-operated press (often called a kick-press or arbor press) lets a single operator exert great force easily. For instance, the Potter USA Quick-Form Press uses a special cam so a jeweler can “exert maximum force with minimal effort”. This press can bend rings, cuff bracelets, napkin rings or even spoon blanks in one station, without hydraulics. It comes with an assortment of forming dies (half-round, flat, etc.) that match typical jewelry profiles.

Larger shops may use a hydraulic bench press. Even a 10-ton press (like Potter’s Tortolita model) is compact enough for a studio. Such a press has two smooth platens that can hold various curved dies or rolling tools. As one maker notes, the 10-ton Tortolita is “designed to form metal safely and efficiently in a jewelry studio environment”. Operators place the band between the platens or over an inserted die and pump the hydraulic ram to bend the metal. These machines excel at very thick metal or multiple bends (for example, flattening and then curling a strip) that would be tiring by hand. Some small machines even double as disc cutters or stakes when no bending is needed. In all powered presses, proper die selection and stroke control are key to avoid over-bending.

Materials and Metal Types

Ring and bracelet benders are used with soft and malleable metals. Sterling silver, gold alloys (10K–22K), copper, bronze, and brass can all be shaped easily. Harder materials (like hardened steel or tough alloys) generally require specialized industrial equipment and are not typical in jewelry shops. Each tool has a thickness limit: many hand-held bending pliers or small bench benders can handle wire or strip up to ~10 ga (about 2–3 mm), whereas heavy-duty bench machines can take stock up to ~4 mm thick. For very thick or large rings/bracelets, the metal is often annealed between bends to relieve stress and prevent cracking. (Without annealing, repeated bends will rapidly work-harden the metal.) In practice, jewelers will often cut a band, anneal it, do a rough bend, anneal again, and so on, to achieve a smooth curve. Polished or plated metals also benefit from the use of plastic dies (nylon or Delrin) so the shiny surface isn’t scratched during bending.

Best Practices for Consistent Shapes

-

Use the right form and die. Always choose a mandrel or die that matches your desired final shape. For rings, a round mandrel or semi-circular die gives an even circle. For cuffs, use a cylindrical bar or bracelet jig. Applying uniform pressure is critical: tools with flat jaws, for example, “apply uniform pressure across the metal strip,” which is “essential when creating consistent curve or circular designs”.

-

Bend incrementally and check fit. Don’t try to force the metal in one go. Bend a little, remove and reposition, then bend more. Frequently check the curve against a mandrel or gauge. If the band comes out too open, it can be bent again on a slightly smaller diameter to tighten the fit. (As one user advises, you can bend on one size then move the band to the “next smaller ring size… half moon” die for a final snug fit.)

-

Prevent surface damage. For softer metals, use nylon or Delrin dies/jaws (as supplied) instead of bare steel. This protects the finish. Also, keep the metal well-supported: if using pliers, slide the strip steadily along the jaws rather than bending at a single point, to avoid kinks.

-

Anneal as needed. Anytime the metal feels resistant or springs back, take it out and anneal it. Silver and gold can usually be bent in long curves without issues, but copper and brass harden faster. Annealing (heating to red-hot and quenching) restores ductility and yields smoother, more even bends.

-

Finish on a mandrel. Once roughly bent, it’s common to hammer or roll the band on a smooth mandrel to finalize the shape. For rings, tapping with a rawhide mallet on a steel mandrel makes a perfect circle and removes any minor irregularities. For bracelets, slowly working on the final form by hand ensures comfort and symmetry.

By following these steps and using well-fitted dies, jewelers achieve very consistent curves. One instructor notes that with a good bracelet bender, a craftsperson can “consistently, and very quickly, shape a lot of cuff bracelets” to showroom quality.

Safety and Maintenance

When using any bending tool, safety is paramount. Always secure bench-mounted tools tightly (bolted or clamped) so they cannot twist under force. Wear safety glasses: if a band springs or a small piece breaks, it can fly out. Keep hands and fingers clear of pinch points (especially near the clamping screws and lever pivot). Work gloves can protect against sharp wire ends on thick stock, but avoid loose gloves around rotating parts.

For powered presses, use both hands on the controls and keep hands away from the die area when the ram is moving. Never exceed the tool’s rated capacity (forcing it can cause metal or parts to fail). Turn off and unplug hydraulic units when changing dies or not in use.

Maintenance: Keep the tool clean and well-lubricated. Wipe off filings and debris after use (metal shavings can scratch or rust dies). Oil any pivot points or screws lightly so they move smoothly. Check that all bolts or screws (especially on clamp-style benders) are tight before each session. Replace worn or damaged dies/jaws: a chipped die will give an uneven bend. For nylon or Delrin parts, ensure they are intact (these are sacrificial and will wear out before the metal does).

With proper use and care, ring benders and bracelet benders give jewelers a fast, accurate way to form metal bands. By combining the right tool, die, and technique (anchoring one end, bending in steps, and annealing as needed), crafters can produce uniformly curved rings and bracelets every time.

0 comments