✈️ Global Transportable

🔄 30-Day Returns

✅ 12-Month Warranty

💬 Online Support

✈️ Global Transportable

🔄 30-Day Returns

✅ 12-Month Warranty

💬 Online Support

✈️ Global Transportable

🔄 30-Day Returns

✅ 12-Month Warranty

💬 Online Support

✈️ Global Transportable

🔄 30-Day Returns

✅ 12-Month Warranty

💬 Online Support

✈️ Global Transportable

🔄 30-Day Returns

✅ 12-Month Warranty

💬 Online Support

✈️ Global Transportable

🔄 30-Day Returns

✅ 12-Month Warranty

💬 Online Support

Tooltos Dual Layer Jewelry Casting Burnout Furnace 1150°C with Separation Plate

- 105 in stock

- Inventory on the way

Description

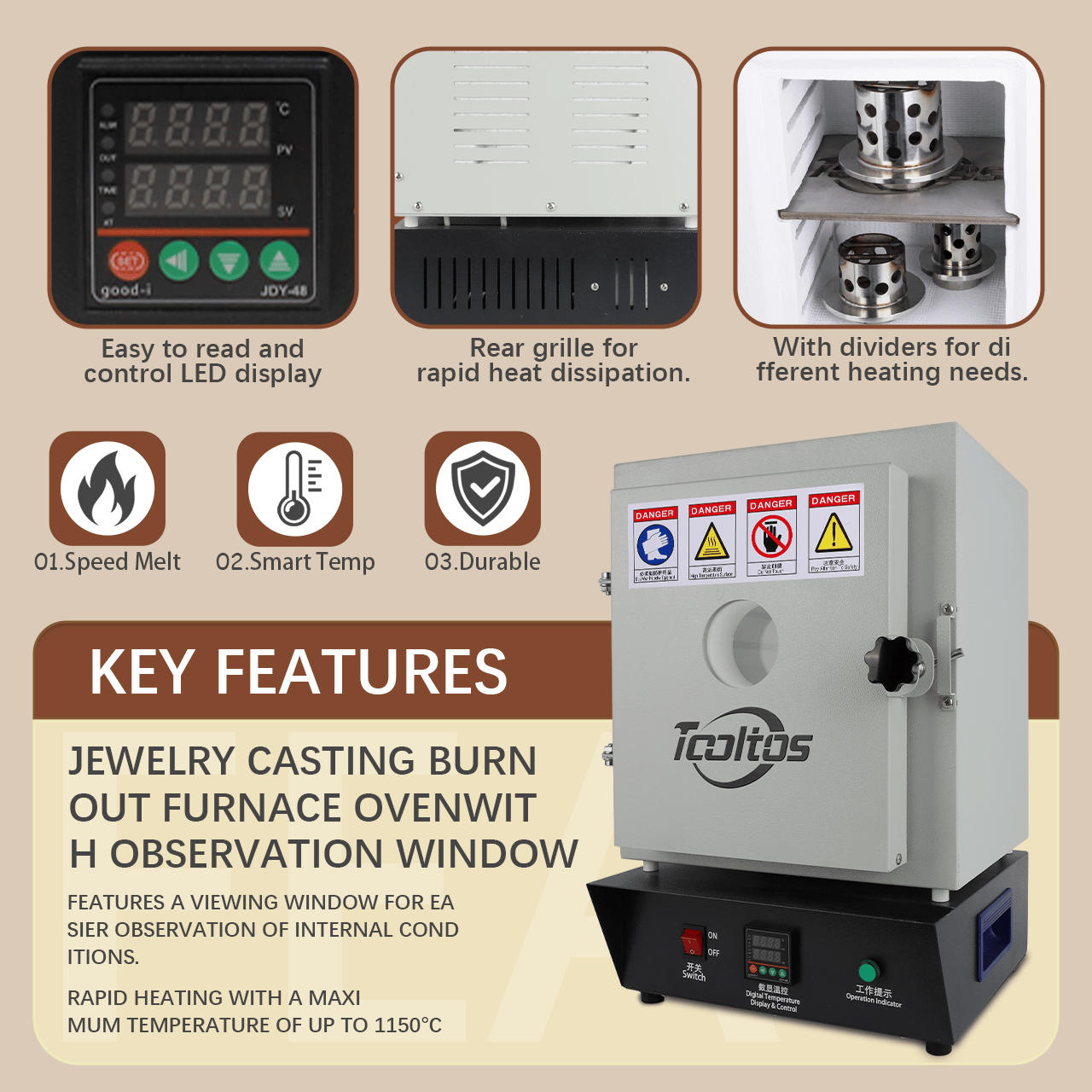

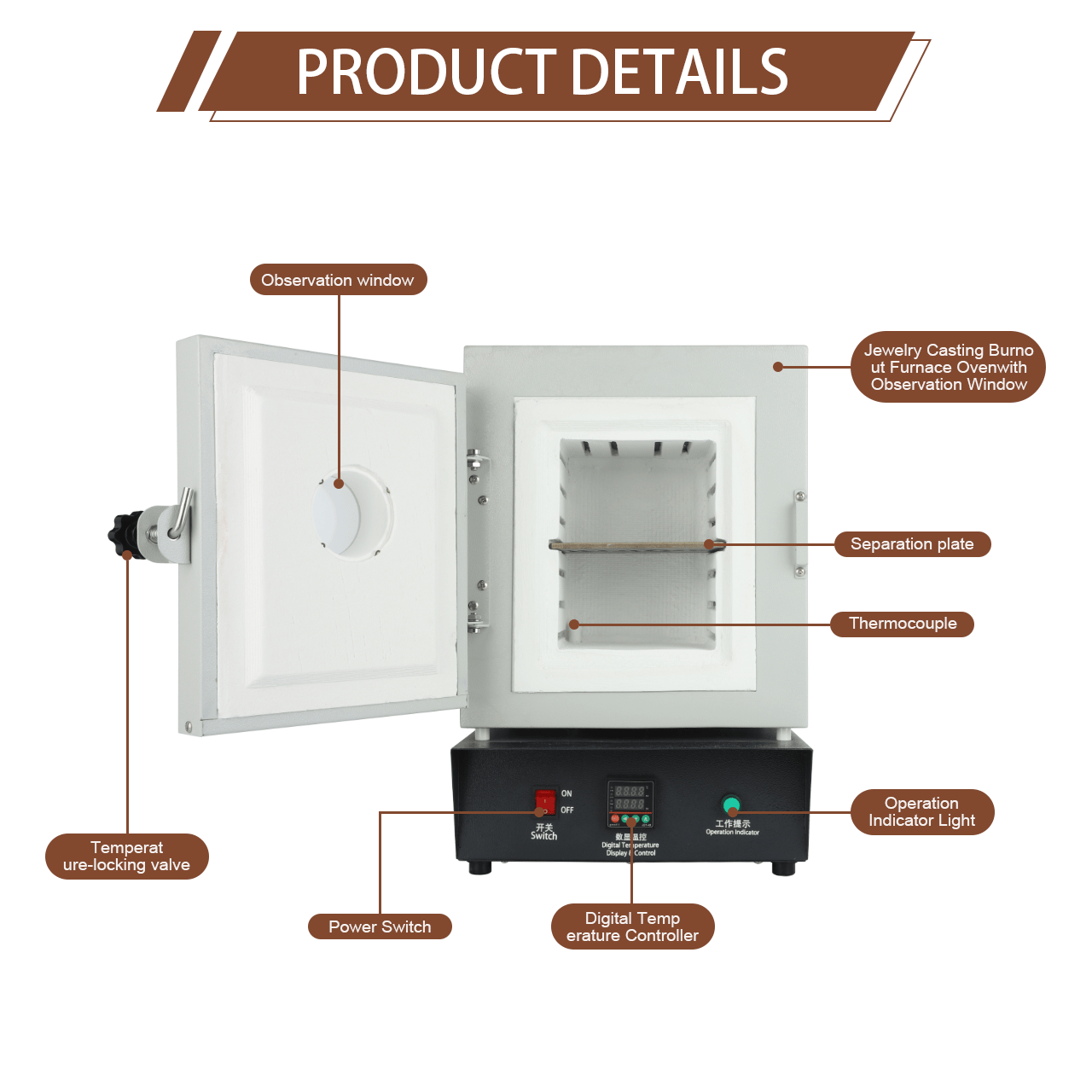

🔥 Dual-Layer Jewelry Casting Burnout Furnace 1150°C

Double Your Casting Capacity with Removable Separation Plate

Process two 4" × 7" flasks simultaneously or use full chamber for larger projects. Perfect for professional jewelers looking to maximize productivity without buying a second furnace.

🆕 What's New

- ✨ Removable Separation Plate - Transform into dual-layer system instantly

- ✨ Flexible Configuration - Single or dual-layer based on project needs

- ✨ Professional Steel Construction - Durable chassis with heat-resistant coating

- ✨ PID Digital Control - Maintains ±2°C accuracy

💎 Key Features

- 🎯 Dual-Layer Capability - Run two burnout cycles simultaneously, double your output

- 🎯 High Temperature - Max 1150℃ within 60–90 minutes

- 🔍 Observation Window - Monitor both layers safely in real time

- 🛠 Universal Voltage - Works with 110V and 220V worldwide

📊 Configuration Options

Single-Layer Mode: Full 7.9" height for large flasks up to 4" × 7"

Dual-Layer Mode: Two levels (3.9" each) for flasks up to 4" × 3.5" each

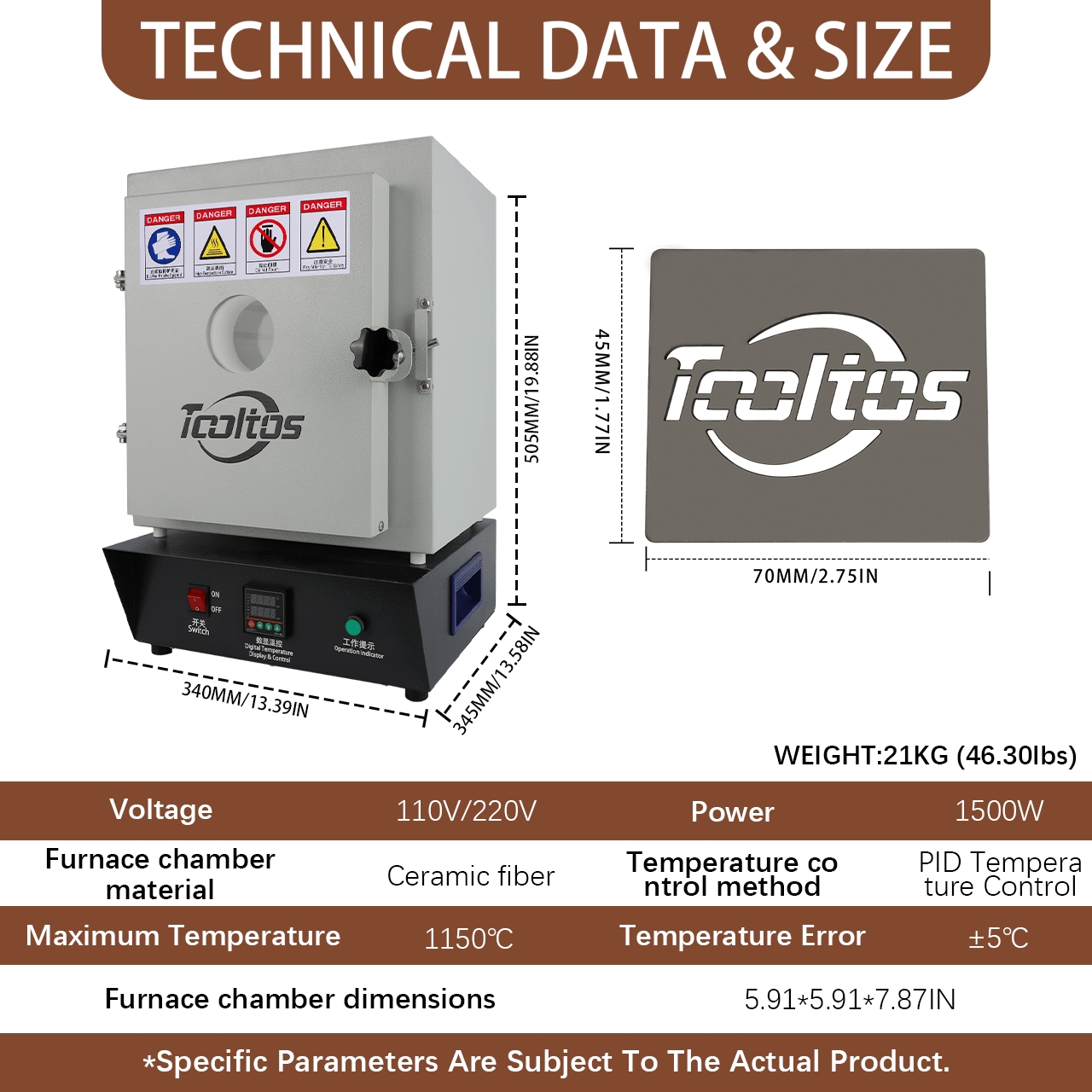

🔬 Technical Specifications

| Max Temperature | 1150°C (2102°F) |

| Chamber Size | 5.9 × 5.9 × 7.9 inches |

| Power | 1500W |

| Voltage | 110V/60Hz or 220V/50Hz |

| Control | PID digital temperature controller |

| Material | Steel with heat-resistant coating |

| Weight | 46.3 lbs (21 kg) |

| Dimensions | 13.4 × 13.6 × 19.9 inches |

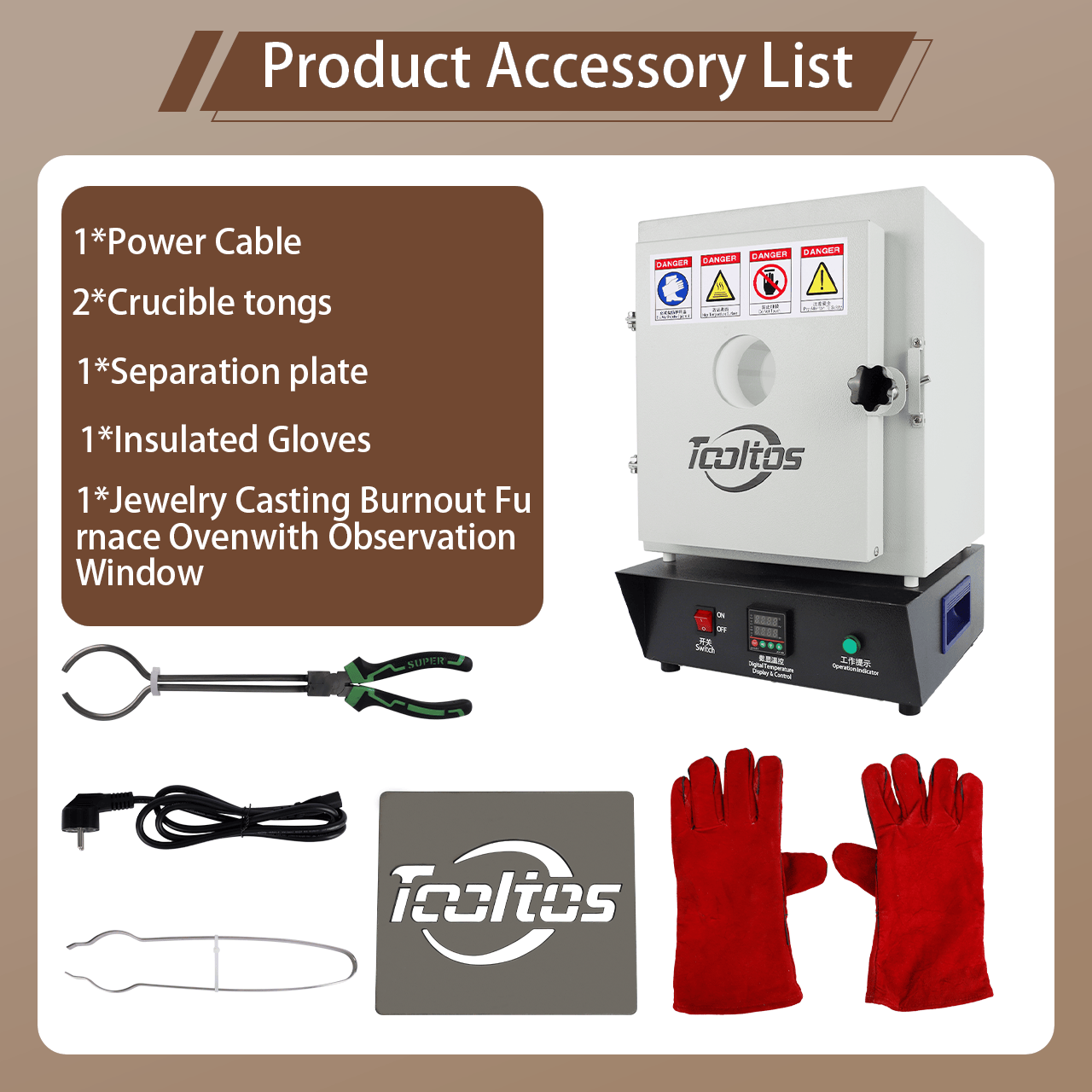

📦 Complete Package

- ✓ Burnout Furnace with Observation Window

- ✓ Removable Separation Plate

- ✓ Heat-Resistant Gloves

- ✓ Crucible Tongs (Steel Bell Pliers)

- ✓ Power Cable (110V or 220V)

- ✓ User Manual with Dual-Layer Schedules

🎯 Why Choose Dual-Layer?

- ⚡ 2x Daily Output - Process two flasks in time for one

- ⚡ Energy Efficient - Same power, twice the volume

- ⚡ Space Saving - No need for second furnace

- ✓ Even heat distribution across both layers

- ✓ Same precision control for both chambers

💡 Best Applications

Single-Layer: Large jewelry, bracelets, necklaces, tall sculptures

Dual-Layer: Production runs of rings, pendants, earrings, small-medium pieces

💼 Typical Workshop Applications

Production Casting Studios:

The dual-layer configuration is ideal for professional casting studios running production schedules. Process two batches of rings or pendants simultaneously, effectively doubling daily output without additional equipment investment. The removable separation plate allows flexibility to switch between production runs and larger custom pieces.

Professional Metalsmith Workshops:

The separation plate design offers exceptional versatility for workshops handling diverse projects. Use single-layer mode for large bracelets and necklaces, then quickly convert to dual-layer for batch processing smaller pieces. The professional-grade steel construction with heat-resistant coating provides reliable performance for daily workshop use.

Jewelry Schools & Training Centers:

Educational facilities benefit from the ability to demonstrate both single and dual-layer casting techniques with one furnace. Students can learn production efficiency strategies while working with professional-grade equipment that matches industry standards.

❓ FAQ

Q: Does dual-layer affect heating time?

A: No. Same 60-90 min to 1150°C with even heat distribution.

Q: Can I use different schedules per layer?

A: Both layers share same temperature but can use different flask sizes.

Q: Easy to install/remove plate?

A: Yes. Simply slides in when furnace is cool. No tools needed.

Q: Steel vs stainless steel?

A: Professional-grade steel with heat-resistant coating provides excellent durability at accessible price.

✔️ Operating Notes

- Allow complete cooling before installing/removing separation plate

- Center flasks on each level for optimal heat distribution

- Leave 1" clearance between flasks and chamber walls

- Minor door gaps are normal for heat expansion and ventilation

📞 Need Help?

Questions about this furnace or need technical support?

- 📧 Email: sales@tooltos.com

- 💬 Live Chat: Available on www.tooltos.com

- 📱 We typically respond within 2 hours

🌍 Worldwide Support

- ✓ Ships to 100+ countries

- ✓ 110V or 220V options

- ✓ Technical support via email, chat, video

- ✓ Replacement parts available

⚡ Transform Your Casting Workflow

Why buy two furnaces when one dual-layer system does it all?

✓ Double production capacity

✓ Save on equipment costs

✓ Reduce energy consumption

✓ Maintain professional quality

Order now and maximize your casting efficiency.

Shipping & Returns

SHIPPING POLICY

Shipping cost is charged by the shipping agency according to the destination, the weight and the shipping method.

Delivery time depends on the destination and the shipping method you choose. Tooltos offers the following shipping methods to ensure the safe delivery of your package

FedEx, UPS and DHL are the fastest delivery methods available. Delivery time is 3 ~ 7 working days to all major destinations. Products weighing more than or equal to 2KG will be shipped by FedEx, UPS and DHL by default.

According to your shopping cart, the system will automatically choose the most economical way for you from FedEx, UPS and DHL.

EMS will take 7~21 working days to arrive. Products weighing less than 1Kg can choose this shipping method, Cost $9.99. Products weighing less than 2Kg can choose this shipping method, Cost $15.99.

Orders are processed and delivered Monday-Saturday (excluding public holidays)

Tip: Tooltos is not responsible for the shipping delay that caused by the severe weather, such as stormy snow or other causes that beyond our control.

30 DAYS RETURNS

We are proud to guarantee 100% satisfaction with all items you purchased on tooltos.com. If there is any dissatisfaction with your purchase for any reason, full refunding, Unconditional Return and 100% Exchange could be accepted within 30 days from the date of delivery.

Questions & Answers

Q1: How to choose voltage 110V and 220V?

A1: Voltage 110V for following countries: United States, Canada, Mexico, Japan, South Korea and some countries of Central and South America.

Voltage 220V for following countries: Australia, Brazil, Europe and most Asian countries.

Q2: Are you a manufacturer or a trading company?

A2: We are a factory trading company providing OEM and ODM services.

Q3: Do you have overseas warehouses?

A3: We have overseas warehouses in the United States, Canada, Australia, Spain, Britain, Russia and Brazil.

Q4: What is the warranty period of your product?

A4: The warranty period of the machine is 1 year.

Q5: How about after-sales service?

A5: We have professional technicians to provide after-sales service. If you have any questions, please contact us.

Social Media

Recently viewed

Tooltos Dual Layer Jewelry Casting Burnout Furnace 1150°C with Separation Plate

Tooltos Dual Layer Jewelry Casting Burnout Furnace 1150°C with Separation Plate

Tooltos Dual Layer Jewelry Casting Burnout Furnace 1150°C with Separation Plate

Tooltos Dual Layer Jewelry Casting Burnout Furnace 1150°C with Separation Plate

Tooltos Dual Layer Jewelry Casting Burnout Furnace 1150°C with Separation Plate

Tooltos Dual Layer Jewelry Casting Burnout Furnace 1150°C with Separation Plate

Tooltos Dual Layer Jewelry Casting Burnout Furnace 1150°C with Separation Plate

Tooltos Dual Layer Jewelry Casting Burnout Furnace 1150°C with Separation Plate

Tooltos Dual Layer Jewelry Casting Burnout Furnace 1150°C with Separation Plate